KHARE AGROMECH INDUSTRIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHARE AGROMECH INDUSTRIES P.LTD.

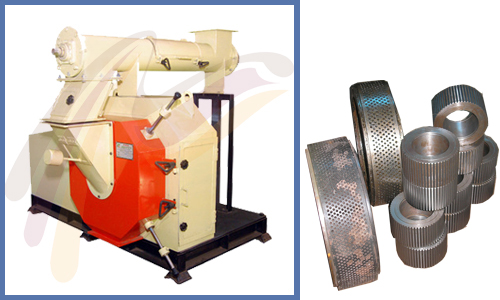

Pellet Mills

The Pellet Mills we offer are designed using the latest technology for accurate and maximum output. The pellet diameter ranges from 2 mm to 25 mm capacity that can vary with the type of material and various other factors.

Various pelleting application include Poultry / Cattle feed Pellets, Organic Fertilizers Pellets Plastic Waste Pellets, Manure Pellets, Gypsum Pellets, Micro Nutrient Pellets, Kaolin Pellets, biomass fuel pellets etc.

We offer pellet mills which are capable of producing pellets of diameters ranging from 1mm die to 20mm die.

Front door, Feed chute and conditioners are made of SS 304 - grade stainless steel for long life.

Feed chute is equipped with a magnet to arrest the ferrous material by going in to pelleting chamber.

Both the pullies are dynamically balanced along with the die assembly.

One or more conditioners can be added for better cooking, Pelletability and digestibilities of the feed.

Crumbler

The Crumbler Roller are made of very durable chilled cast iron thus reducing the operational cost.

Crumble Roller are easy to exchange.

One roller is fixed and other is adjustable & Spring loaded in order to adjust the gap between two rollers. Rolle gap can vary from 0 to 10mm.

Rollers are dynamically balanced.

Capacitation available from 2.5 to 15 TPH.

Features :

Excellent reliability and superb performance

Flexible enough to meet the requirements of the customer

Highly durable and long life servicing because it has got a robust design

Easy to operate.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.